Case Study Node Image

A pulp & paper company in the Canada were dissatisfied with the reliability of the mechanical seal used in its Chlorine Dioxide generator pump.

Product Types

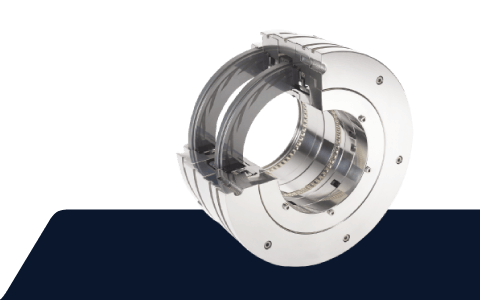

Cartridge Mechanical Seals

Accessible Text

Fantastic seal life for notoriously difficult application

A pulp & paper company in the Canada were dissatisfied with the reliability

of the mechanical seal used in its Chlorine Dioxide generator pump.

This critical process pump is essential for operation of the pulp mill with changing the pump

taking 12 hours and the site just holding 4 hours supply of Chlorine Dioxide. The existing

competitors seal was used along with an API Plan 54 seal support system which was unable to

warn the operator in the event of an inboard seal face failure. The seal had a mean time between

failure (MTBF) of just 15 months which was deemed unacceptable to the customer

who approached AESSEAL® for an alternative solution.

AESSEAL® recommended installing a FIDC™ dual seal along with a water management system.

The new solution was installed in March 2017 and has proved to significantly improve the MTBF

of the pump. The seal ran without problems for four years, when at a planned maintenance

the seal was replaced (although the condition was still good). The plant has seen an overall

improvement in reliability and reduced the amount of water consumed, saving over 3 Million

gallons in 4 years. In addition the quality of the Chlorine Dioxide was improved as there was less

dilution.

Virtually all R-8 & R-10 Chlorine Dioxide operators have experienced reliability problems at some

point with their P-40, Chlorine Dioxide Generator Circulation pumps because it is one of the

hardest applications in an NBSK pulp mill. 2 year seal life is usually considered a good run, but in

this case 4 years may be the longest lived seal in this application anywhere in Canada. AESSEAL

Canada would like to know if there is another mill that has done better? We are always looking

for new and innovative ways to make this a more reliable and safe pump and seal application.

If you can share your secret, we are all ears. If you want to know our secret, we will be happy

to provide a proposal for our proven solution.

aesseal.com/info

‘Seal life improved to 4 years on P-40 ClO₂ Pump’

Industry: Pulp & Paper

Product: FIDC™ and Water Management System

Application: Chlorine Dioxide Generator Pump

MTBF Increase: 220% (and counting)

Water Savings: 766,800 Gallons each year

Reference N.O: CS0120

A pulp & paper company in the Canada were dissatisfied with the reliability

of the mechanical seal used in its Chlorine Dioxide generator pump.

This critical process pump is essential for operation of the pulp mill with changing the pump

taking 12 hours and the site just holding 4 hours supply of Chlorine Dioxide. The existing

competitors seal was used along with an API Plan 54 seal support system which was unable to

warn the operator in the event of an inboard seal face failure. The seal had a mean time between

failure (MTBF) of just 15 months which was deemed unacceptable to the customer

who approached AESSEAL® for an alternative solution.

AESSEAL® recommended installing a FIDC™ dual seal along with a water management system.

The new solution was installed in March 2017 and has proved to significantly improve the MTBF

of the pump. The seal ran without problems for four years, when at a planned maintenance

the seal was replaced (although the condition was still good). The plant has seen an overall

improvement in reliability and reduced the amount of water consumed, saving over 3 Million

gallons in 4 years. In addition the quality of the Chlorine Dioxide was improved as there was less

dilution.

Virtually all R-8 & R-10 Chlorine Dioxide operators have experienced reliability problems at some

point with their P-40, Chlorine Dioxide Generator Circulation pumps because it is one of the

hardest applications in an NBSK pulp mill. 2 year seal life is usually considered a good run, but in

this case 4 years may be the longest lived seal in this application anywhere in Canada. AESSEAL

Canada would like to know if there is another mill that has done better? We are always looking

for new and innovative ways to make this a more reliable and safe pump and seal application.

If you can share your secret, we are all ears. If you want to know our secret, we will be happy

to provide a proposal for our proven solution.

aesseal.com/info

‘Seal life improved to 4 years on P-40 ClO₂ Pump’

Industry: Pulp & Paper

Product: FIDC™ and Water Management System

Application: Chlorine Dioxide Generator Pump

MTBF Increase: 220% (and counting)

Water Savings: 766,800 Gallons each year

Reference N.O: CS0120

Case Ref

CS0120

Pillars

Country

Canada

Inudstry

Pulp and Paper