Case Study Node Image

A leading UK company is set to save more than £5 million over five years following the installation of AESSEAL® LabTecta®OP bearing protectors.

Product Types

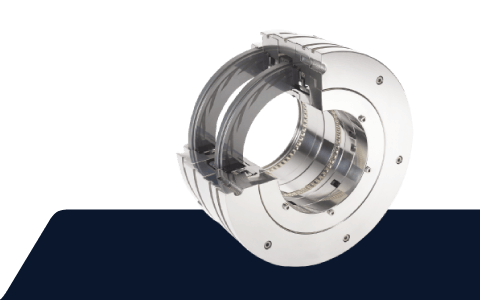

Bearing Protection

Accessible Text

AESSEAL® helps UK firm to multi-million pound savings

A leading UK company is set to save more than £5 million over five years

following the installation of AESSEAL® LabTecta®OP bearing protectors.

The Aircrete block manufacturer specializes in road contracting and in the production of

construction materials and building products. It has a workforce of around 7,000 people

employed on more than 400 sites across the UK.

Its range of building products includes lightweight Aircrete concrete blocks. However, in the

course of the production process, the company was experiencing the persistent bearing

failure due to contamination of the bearings in the wheels of the autoclaves. Each autoclave

has more than 100 wheels, and with some 3,400 failures a year, the MTBF was running at

less than seven months. The result was a yearly bill of almost £620,000 a year in repairs and

maintenance, in addition to the loss of an average of two hours a week in downtime, which

amounted to a yearly cost of £728,000 in lost production.

The total cost to the company, including repairs and maintenance, downtime, and labour costs,

was around £1,400,000 a year. The solution was the installation of new wheels fitted with

AESSEAL® LabTecta®OP bearing protectors, which are specifically designed to prevent fluid

leakage. The total cost of this investment, at just under £1,100,000, means that it will have paid

for itself in under a year. Savings over the next five-year period will be more than £5.5 million.

‘More than £5.5 million saved over five years’

Industry: Construction

Product: LabTecta®OP

Application: Autoclaves

Savings: >£1 million each year

Reference N.O: TD3084392

A leading UK company is set to save more than £5 million over five years

following the installation of AESSEAL® LabTecta®OP bearing protectors.

The Aircrete block manufacturer specializes in road contracting and in the production of

construction materials and building products. It has a workforce of around 7,000 people

employed on more than 400 sites across the UK.

Its range of building products includes lightweight Aircrete concrete blocks. However, in the

course of the production process, the company was experiencing the persistent bearing

failure due to contamination of the bearings in the wheels of the autoclaves. Each autoclave

has more than 100 wheels, and with some 3,400 failures a year, the MTBF was running at

less than seven months. The result was a yearly bill of almost £620,000 a year in repairs and

maintenance, in addition to the loss of an average of two hours a week in downtime, which

amounted to a yearly cost of £728,000 in lost production.

The total cost to the company, including repairs and maintenance, downtime, and labour costs,

was around £1,400,000 a year. The solution was the installation of new wheels fitted with

AESSEAL® LabTecta®OP bearing protectors, which are specifically designed to prevent fluid

leakage. The total cost of this investment, at just under £1,100,000, means that it will have paid

for itself in under a year. Savings over the next five-year period will be more than £5.5 million.

‘More than £5.5 million saved over five years’

Industry: Construction

Product: LabTecta®OP

Application: Autoclaves

Savings: >£1 million each year

Reference N.O: TD3084392

Case Ref

TD3084392

Country

United Kingdom